Background

Innovation at the home is a personal daydream for the engineer. Where some individuals see broken, inefficient, or problematic processes, I see opportunity for improvement. It has never been easier to personally innovate with the ease of access to hobbyist fabrication capabilities, such as 3d printing. Furthermore, the sudden cultural shift of the entire world significantly increasing the residence time of billions of people in their homes across the world as resulted in the compounding frequency of problem identification within the household for the engineer-minded person. This ailment can rapidly become overstimulating and distracting if not treated quickly.

The secondary step of the problem identification is to ask if the solution is applicable to a broader audience, or for that matter, if the problem in mind is even a problem for your cohabitants, i.e. Wife asks: 'Well, what's in it for me?' I have been informed that I have much work to do in this secondary step.

That being said, I have identified one of the most time sinking problems in this new work from home environment soley purpetuated by my desire to drink good tea. Recently, I have learned about the more diserable flavor profile of properly steeped loose leaf tea. More control in concentration, better diffusion through the hot water, and properly timed for desired strength, the positives are overwhelming.

| Tea Type | Time | Temp |

|---|---|---|

| Green Tea | 3 minutes | 175 °F |

| Black Tea | 5 minutes | 195 °F |

Problem Identification

Me, I'm personally more of a Black Tea guy, but closer to 5 minutes and 30 seconds for my ideal steep time. This. is. my. problem. I can't sit still for 30 seconds without an interruption in my train of thought, let alone be ready to stop the diffusion process of my tea after 5.5 minutes exactly. 3 minutes to 10 minutes is the worst time inteveral for any process requiring intervention. Too short that you can't accomplish anything else, too long that you can't sit there and wait for the time to pass without feeling like a non-worthy contributor to the increase of entropy in the universe. Fortunately for me, I can solve this problem.

Objective Statement

Automate precision tea steeping process for a consistent quality tea drinking experience.

Reading this out loud makes it seem just as ridiculous as it is.

The litany of responses: - Why not just set a timer on the microwave or phone? - It can't be that much of a difference... - The worst 'Preparing the tea is a part of the experience' etc.

No, I needed this to be solved much like a nail needing a hammer, or however that phrase goes. The next step in any overengineering adventure is to set up desing constraints

Design

- Must hold my tea steeper.

- Must steep tea for specific amount of time.

- Created with things on hand (specifically I have an extra arduino, some motors, and 3d printing capabilities).

- Minimum Viable Product (MVP). Any design at first must be the least amount of input to get the output; improvements and feature additions are future Quincy problems.

Ah, the last point. A good engineer would probably go through the design process with mass production in mind, create something applicable to many people, or make it adaptable for many use cases. Not this. While it never is a problem with tea bags to fit into any mug, not every tea steeper is the same. In fact, I only have one that I truly like: FORLIFE Tea infuser

This overpriced perforated stainless steel cylinder fits over a mug of choice perfect for any tea officianado. Ensuring even surface area contact between the dried leaves and water.

So the device must be desinged around the dimensions of the infuser, submerge entirely into water for a desired amount of time, then remove the infuser from the water when the time has passed. Easy.

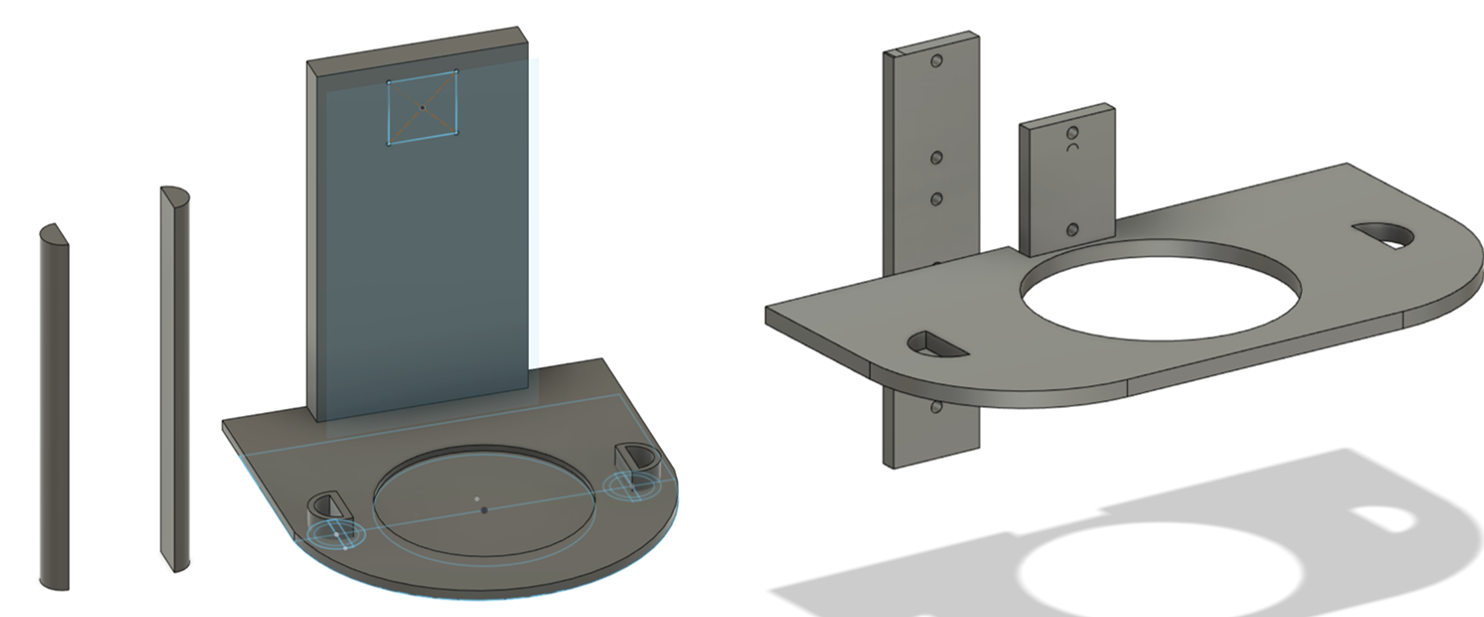

I chose to model the entire device within Fusion360, I am by no means a CAD expert, but I can at least develop my own intuition around how I needed to build the device.

A few M5 nuts and bolts, and sufficiently absurd linear guide half circles and I'd call it good enough.

The most difficult challenge was to figure out how to displace the infuser in the Z axis sufficient enough to ensure you didn't start too high or low relative to the mug and traveled the appropriate amount of distance to steep the tea properly in the mug.

I found a model rack and pinion linear actuator on Thingiverse, that I was able to adapt to my model base. The only stepper motor I had available for this project was the bloody infamous 28BYJ-48. Just barely strong enough to lift the required weight.

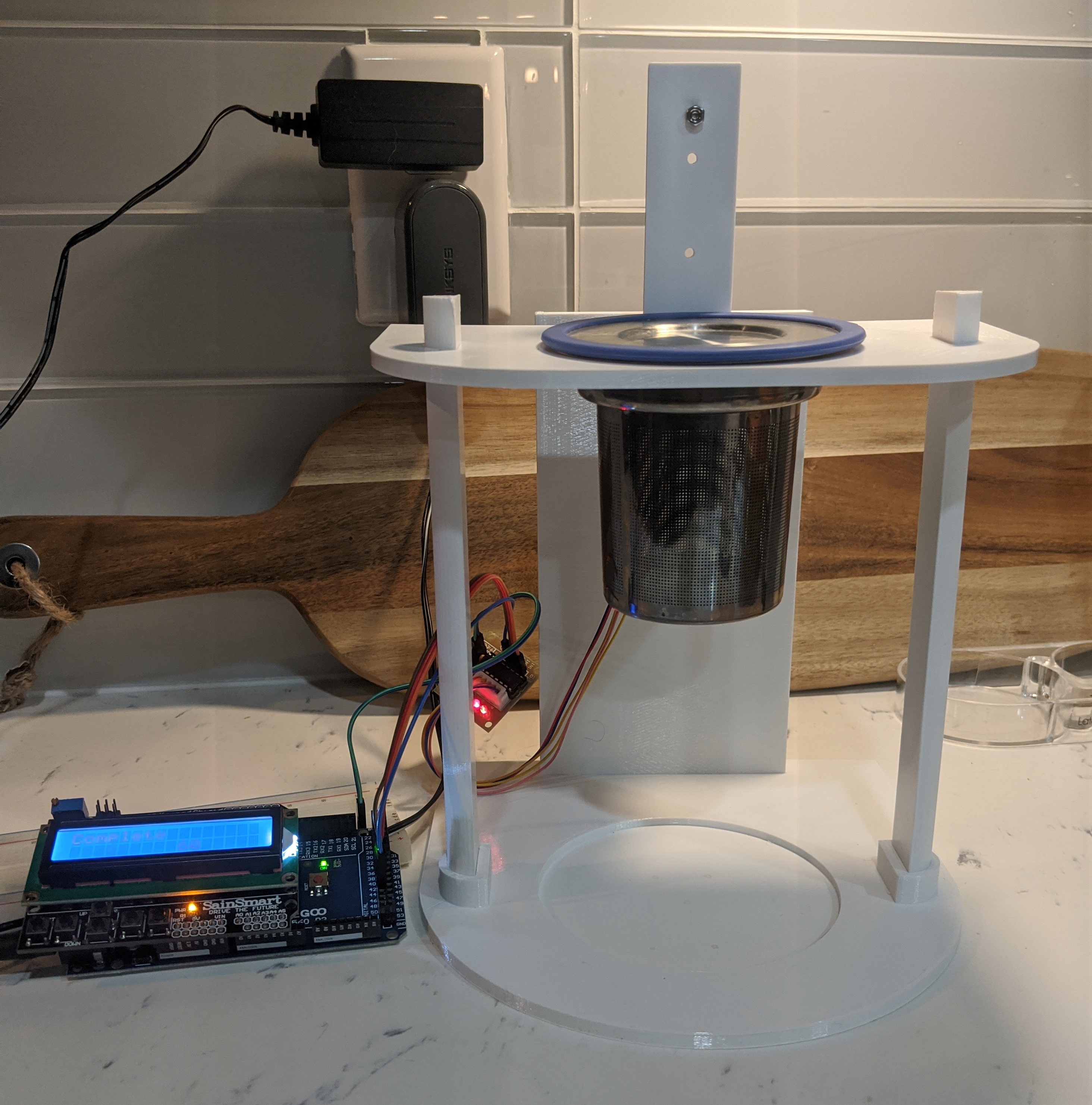

9.5 hours of 3d printing later, a few beers and a night of god-awful code practices and voila!

The Automatic_Tea_Steeper_v1.

How to use this bad boy?

- Using the LCD Crystal on an Arduino and the ULN2003 Driver board, a user can first input their own steep time, for the sake of the design to a resolution of 30 second intervals.

- Hit select on the LCD Display

- Watch your tea steep, or don't, it's automatic and will be perfect everytime!

Below are two videos of the process for the readers enjoyment.

Conclusion

Could I have soldered up the connections so I don't have to use a breadboard? Maybe. Did I 3d print the base in the slowest way possible to save myself from bolting two things together? Yes. Do I need two outlets because I didn't want to jump the 5v connection for the ULN2003 from the arduino for risk of lowering my inputs? Absolutely. Would linear bearings with appropriate tolerances give a smoother operation? Sounds lame. Does it work everytime even with a 3d printed gear taking the highest fatigue limit path with constant load? Damn right it does.

All in all, this thing is a beaut. It has worked phenomanally for the most part, though I think the plastic gears will give out over time. Furthermore, I didn't even have to redesign any 3d model thanks to meticulous bolt placement and flexibility in in construction.

To recap:

- Must hold my tea steeper.

✔ - Must steep tea for specific amount of time.

✔ - Created with things on hand (specifically I have an extra arduino, some motors, and 3d printing capabilities).

✔ - Minimum Viable Product (MVP). Any design at first must be the least amount of input to get the output; improvements and feature additions are future Quincy problems.

✔

I don't know what problems future Quincy will have, but I can assure you it will not be bitter tea any time soon. And that is what this is all about. The part that excites me the most is that it only took some design time using free software and open source hardware and I was able to solve a problem on hand in my household with a personal touch. The next step that I am trying to correct is to help that diffusion of innovation to others, much like the diffusion occuring during the tea steeping process. In academic writing (my current least favorite daily activity), the work I convey in that medium may reach an audience of 10-100. With jovial overengineered blog write-ups I may reach an audience of 0-10^5, the uncertainty is thrilling!

If you appreciated this project please let me know, the stl files and arduino code are here. Comments are always welcome!

I'm considering this problem solved.

QED.

Comments

comments powered by Disqus